Who we help and how

Anderson Global is a foundry mold design, engineering, and production facility. The high-performance molds we manufacture stand up to demanding processes and rapid cycle times while producing consistent, accurate castings.

Our best customers:

- Have complex casting problems they can’t solve on their own – like multiple cores, intricate geometry, solidification challenges, and more

- Lack the capacity or internal expertise to develop a fully engineered solution, including simulation, design for manufacturing, and reverse engineering

- Need a trusted partner to build an accurate mold to complex specifications

- Want to pull from cross-industry best practices to modernize their foundry’s processes and capabilities

Our process

While each mold is different, we’ve standardized our process to ensure you get the best product possible. Here’s an overview of the steps you can expect.

-

Design

Whether you come to us with completed blueprints or a blank page, our process always starts with design. Our full design process starts by understanding your foundry’s needs and capabilities. From there, our design engineers iterate a design with the help of our simulation software and years of industry experience. Finally, we conduct a thorough design review to ensure that the mold can be manufactured and will produce the correct casting before we build the final model.

-

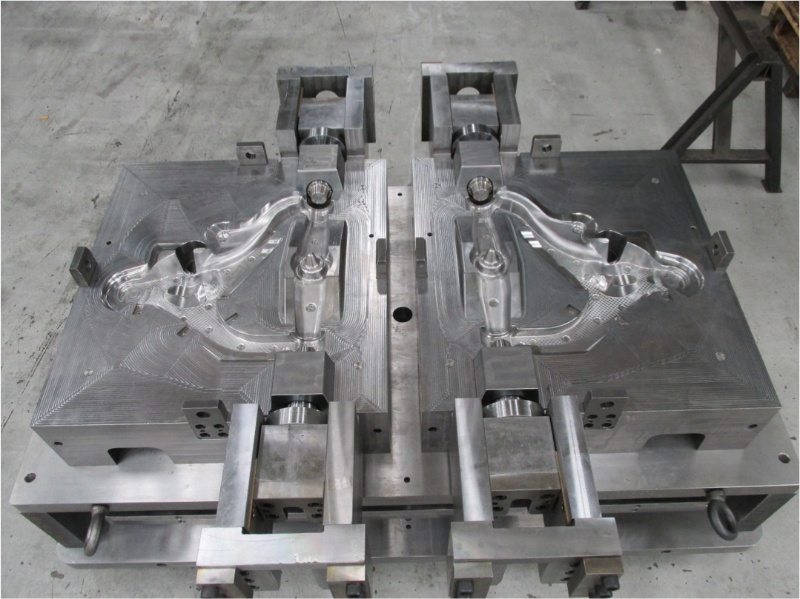

Machining

Now, we cut the metal. As we machine your components, we rely on the latest technology in automation and CNC machining, as well as the experience of our journeyman patternmakers, to keep our tolerances tight, our timelines accurate, and our designs up to date with any changes so your mold is exactly what you expect.

-

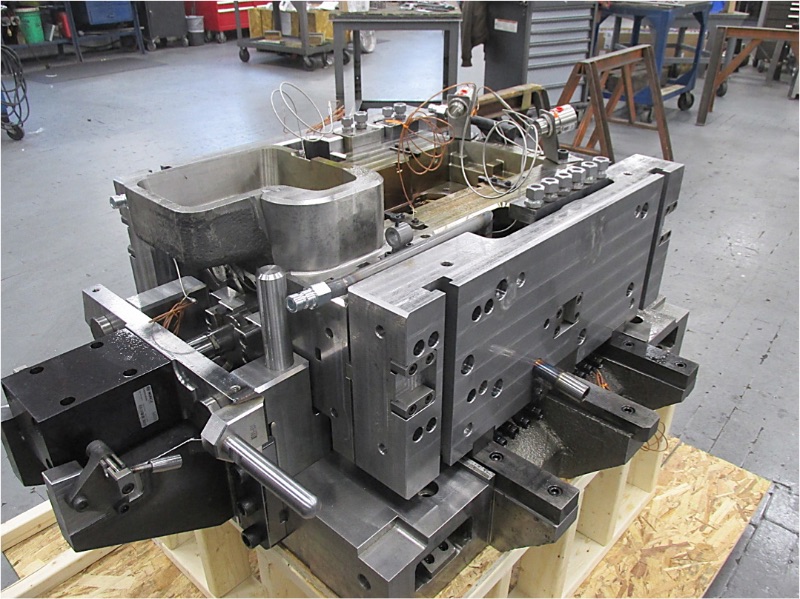

Final finishing and assembly

In this last step, skill and experience are everything – it’s our last chance to make sure everything meets your requirements and functions as it should. Fortunately, our journeyman patternmakers have been benching, applying surface finishes, checking quality, testing component functionality, and putting everything together for decades. They’re up to the challenge.

Premium foundry molds

Attention to detail delivers value in the long run

We aren’t in the business of cutting corners. When you partner with us for a premium mold, you:

- Produce accurate castings, not faulty parts, from the first pour

- Rely on durable molds that don’t need constant service, which means less downtime

- Uncover process efficiencies that allow your metal casting team to maximize production

- Gain the on-call expertise of engineers, journeyman patternmakers, and program managers to troubleshoot and answer questions

Getting your quote

Our quoting process is a conversation, not just a list of line items. The more you can tell us about your expectations, capabilities, timeline, design complexity, and desired materials, the easier it will be to build out your pricing options together.