Eagle Aluminum Permanent Mold Castings had had enough.

Located in Muskegon, MI, the foundry primarily manufactures components for the automotive, oil & gas, agriculture, and heavy trucking industries.

But repeated errors and delays at the hands of a vendor providing tooling on the cheap put their ability to meet customer demands at risk.

Eagle was at a crossroads when they first engaged Anderson Global: Continue with prior disappointing vendor relationships that ultimately risked their reputation among customers or form a partnership with a turnkey tooling partner who would put a stop to all the unforced errors.

Eagle Aluminum President Mike DeVoursney brought Anderson on board when he joined the foundry in 2017. While they weren’t working on major projects, Mike was impressed by the responsiveness of the sales team.

“If we had an issue with one of the tools that they serviced, we would see somebody in here either the next day, or at the very latest that same week,” Mike said.

Mike liked that Anderson Global provided quotes almost immediately after discussing a service project. They included firm timelines so Eagle Aluminum could notify customers of why the tooling system was down and when it would be running again.

That level of detail and dependability was what Mike needed in a tooling provider.

Faulty tooling sets everyone back

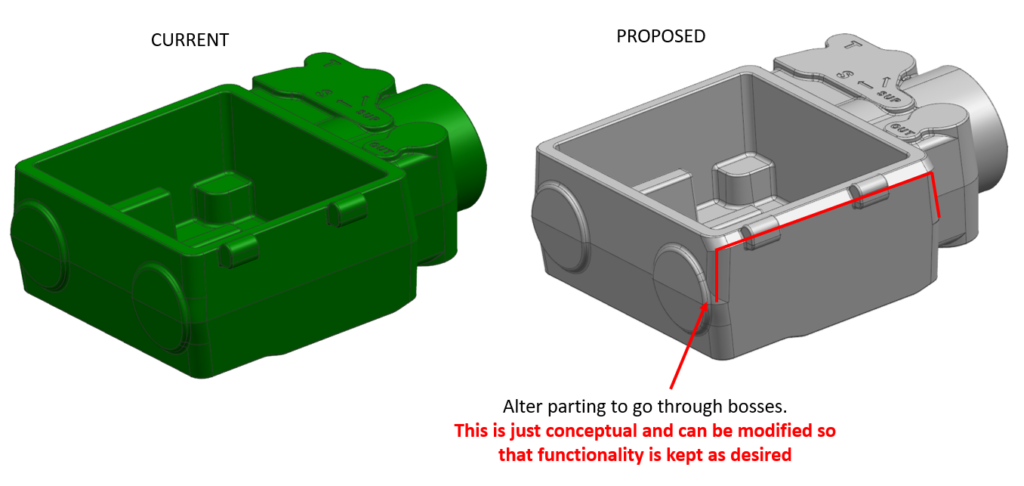

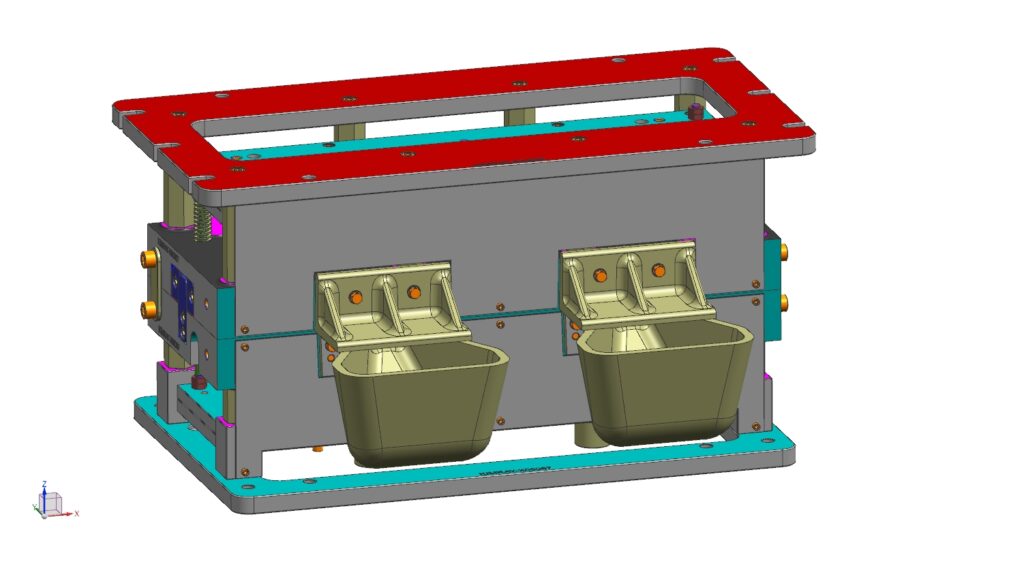

One of Eagle Aluminum’s big oil and gas customers needed a new housing to regulate the separation of water and gas from crude oil. The housing parts were initially cast with two separate tools, but the customer wanted it done with just one.

And Eagle needed this project to go well. They’d had some rocky experiences with this customer in the past.

Eagle Aluminum had contracted with tooling suppliers that didn’t communicate. Tooling was delivered three to six months late without proper warning. And it often had parting line and objection issues, missing features, or cooling lines that weren’t added.

They had to send the entire tool system back to the supplier, which set projects back another six to eight weeks.

All that delayed production and jeopardized Eagle Aluminum’s relationship with the customer.

Tooling delays create a trickle-down effect that hurts everyone involved.

“Having an inferior tooling supplier manage these tools could be devastating to our reputation as a company and to our customer as well,” Mike said.

It hurt Eagle’s reputation, because they couldn’t meet set timelines. And that threw off the customer’s production schedule, which is extremely costly in the oil and gas industry.

That’s why there aren’t many second chances in this business.

Reliable turnkey tooling providers won’t drop the ball

For this project, Eagle Aluminum turned to the most reliable toolmaker they knew, Anderson Global.

Anderson visited Eagle’s facility to analyze their current casting process and facility layout.

Eagle gave the Anderson engineering team a general concept of the desired gating and riser scheme.

Expert foundry engineers reviewed the material and put together a complete tooling design. Then they ran a mold flow analysis and found a couple pockets of porosity that could have jeopardized casting strength.

The Anderson team modified their designs and ran solidification simulations until they developed a gating scheme that evenly fed both ends of the part to eliminate porosity.

Anderson also used the mold flow analysis to predict the tool’s run rate. That helped Eagle provide their customer with accurate quotes and timelines for the production part approval process (PPAP).

Eagle Aluminum presented their customer with the final mold flow analysis, got approval for the tooling on their first try, and kicked off the project without a hitch.

Anderson Global’s pricing was not the lowest compared to their competition. However, their engineering capabilities, mold flow analysis, and reliable communication more than offset the additional cost. Eagle Aluminum needed dependable tooling from the best in the business, not another discount and the problems that come with it.

“Anderson Global’s reliability with delivery and communication is beyond anything I’ve seen,” Mike said.

Quality castings and tight timelines satisfy customers

For Eagle Aluminum, the two key aspects of a successful tooling project are timing and first shot rate.

And for this project, the tooling came in on time and produced quality castings upon installation.

Eagle Aluminum has come to expect nothing less from their trusted tooling partners.

“We were able to provide parts on time with zero defects, and we got PPAP approval with our first try,” Mike said. “It was great to see our customer satisfied with what we were able to provide.”

The benefits also trickle down to the foundry team. Technicians are happy to be assigned these housing parts because they get to work with reliable tooling.

“When a tool comes in and it performs as the design intends — it bolts up perfectly to our tools, it runs with the exact run rate, there are no porting line ejection issues, all the features are there — our team members get excited,” Mike said. “We’re able to do what we say we’re going to do, and it makes their lives easier as molders.”

The full tooling package for USA foundries

Is faulty or delayed tooling holding your foundry back?

Anderson provides turnkey solutions that help American foundries thrive. And we could help you, too.

Get the complete tooling package with mold flow analysis, solidification simulations, engineering assistance, and reliable tooling supply.

If you need expert analysis, open communication, and reliable delivery, turn to the foundry tooling experts and get the job done right the first time.