Foundry molds that produce world-class castings

Anderson Global designs and builds premium molds for foundries that need perfect parts from the first pour.

Work with one experienced partner for your whole project

Imperfect parts, damaged molds, and process bottlenecks – all these problems can be solved with experience and intelligent, thoughtful design.

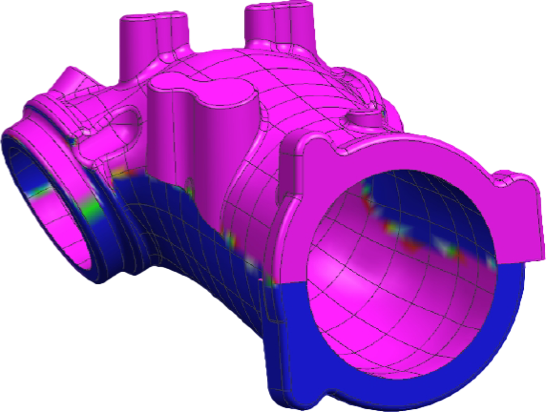

We’ll validate a design you already have, make suggestions for castability, or start from square one. We use simulations to move from drafted design to manufacturable mold quickly.

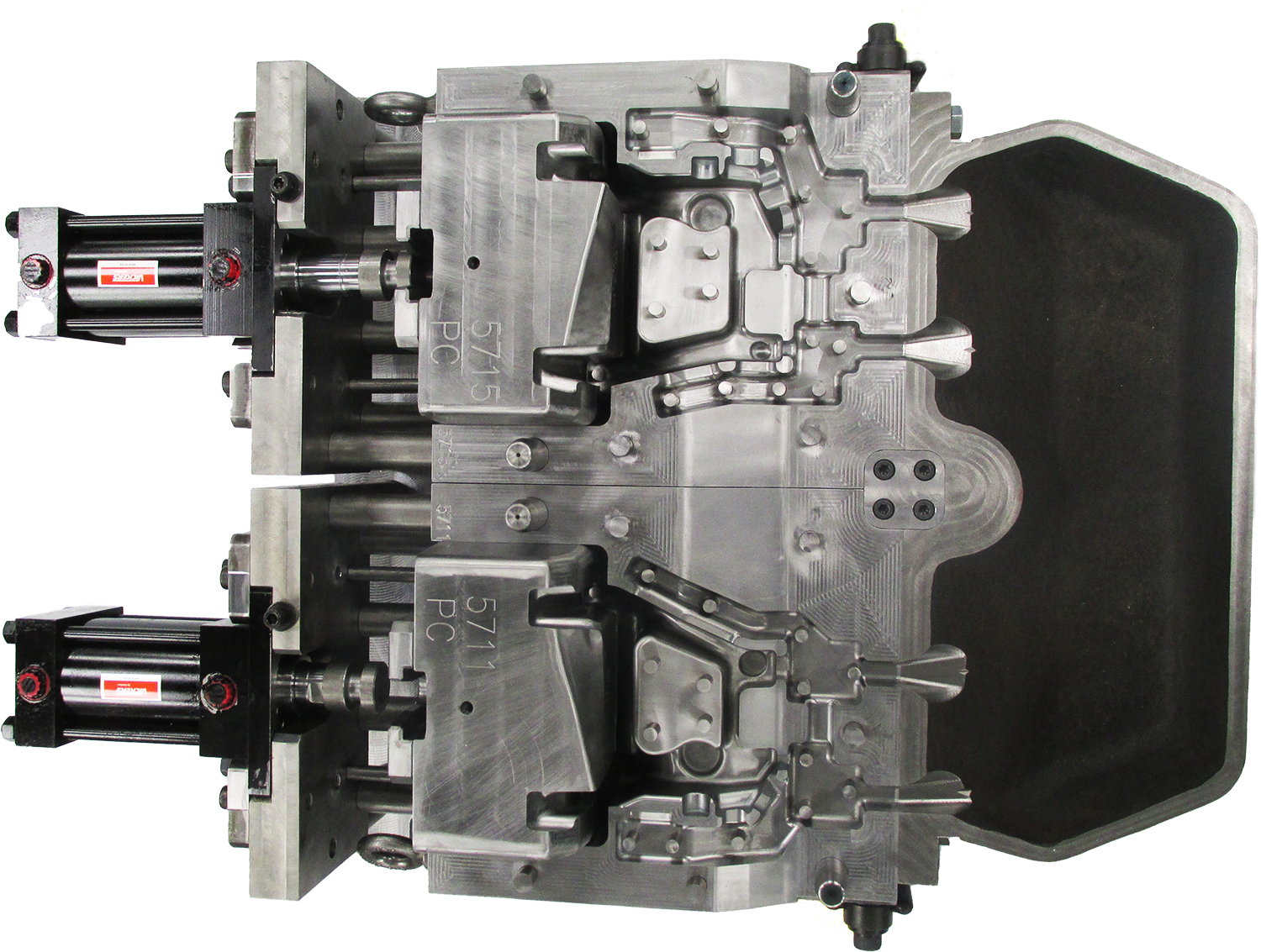

Cast quality parts from the first pour

If your supplier cuts corners on your mold, they’re chipping away at your part consistency, equipment durability, and casting accuracy. That all costs money you didn’t plan on spending.

We take pride in getting things right the first time. Our molds stand up to the wear and tear of metal casting to create superior parts pour after pour, year after year. All with less maintenance and less downtime.

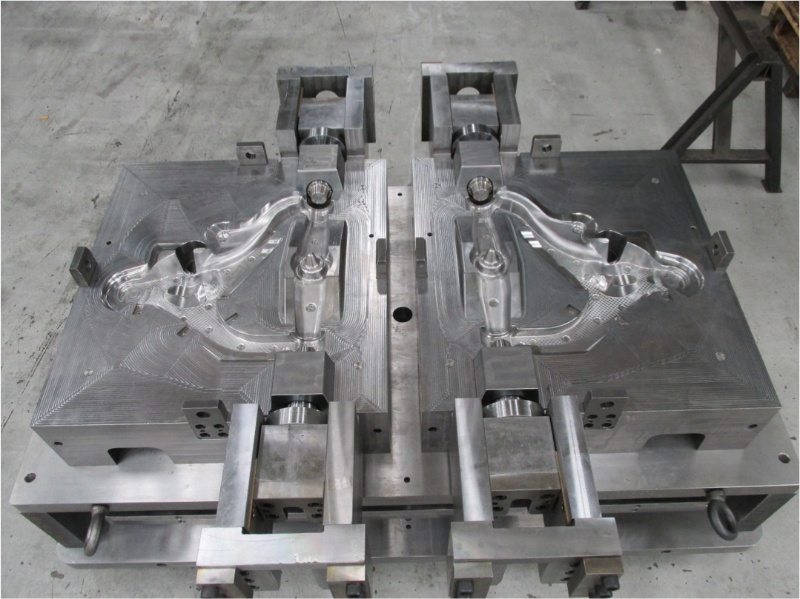

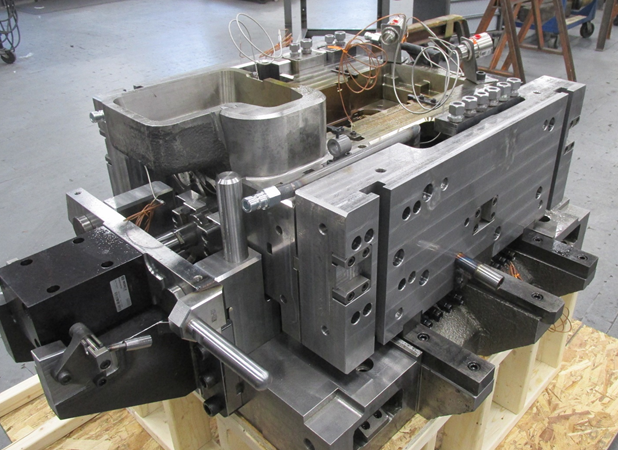

Overcome complex mold challenges

Tight tolerances, rapid cycle times, multiple cavities, intricate cooling systems — you can’t pour cutting-edge castings without an exceptional mold. No project is too complex for our team. That’s why we invest in expertise.

Avoid downtime and project delays with durable molds and responsive service

If something goes wrong, you shouldn’t have to wait for repairs. It jeopardizes your work and your bottom line.

So we build open capacity into our facility’s schedule. It allows us to deliver maintenance, modifications and spare parts in days, not weeks.

Let’s get started on your new foundry mold

Reach out to our team for a quote. We’ll get back to you within 24 hours with options, pricing, and some additional questions about your application.